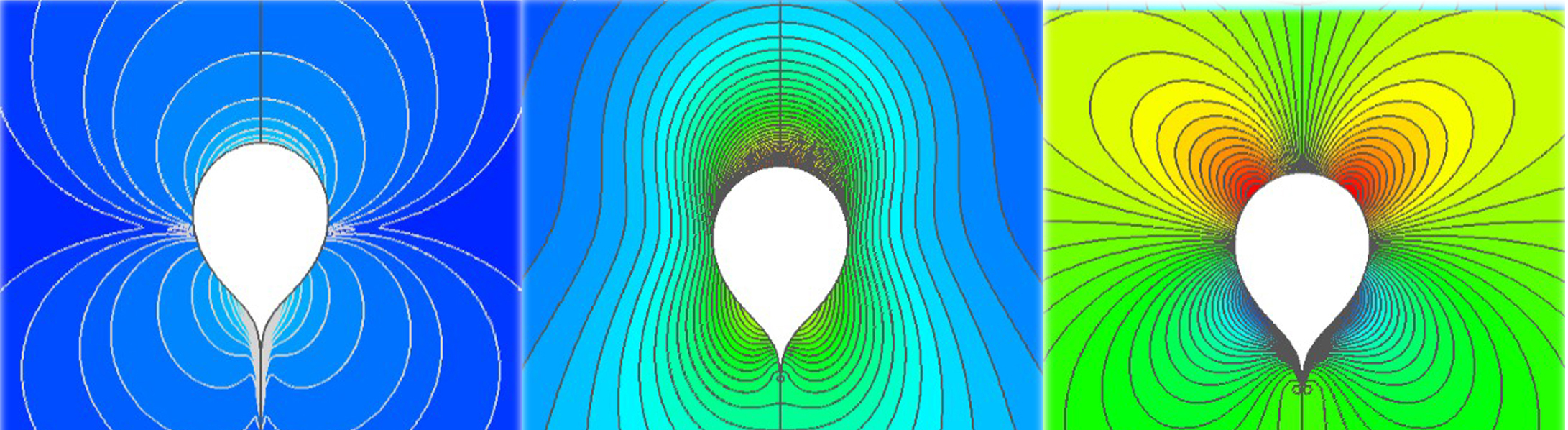

For diverse applications such as polymer devolatilization, fermentation, composites processing, plastic foam processing, gas absorption and others it is of interest to know the rise velocity (hence the residence time) and shape of bubbles in polymeric solutions. It is known that single bubbles rising in quiescent viscoelastic liquids may exhibit a sudden (discontinuous) 3-10 fold increase in their rise velocity, once their volume exceeds a critical value. The abrupt change of the bubble rise velocity is accompanied by a change in the bubble shape from a convex to a cusped or “teardrop” shape. (see below).

Predictions of the effect of fluid elasticity on the shape of a deformable air bubble in very good agreement with experiments.

The motion of air bubbles in complex fluids has drawn our attention because of its numerous applications. Characteristic examples of such applications include: a) bubble removal from structural materials (i.e. cement) through vibration, b) entrapment of air bubbles in many foods to improve their flavor and texture (i.e. chocolate, ketchup), c) prevention of large bubble formation in drilling mud, which may cause dangerous explosions, inhibit production and potentially inflict huge burden on the ecosystem and the finances of oil-drilling companies.