We report experimental microfluidic measurements and theoretical modeling of elastoviscoplastic materials under steady, planar elongation. Employing a theory that allows the solid state to deform, we predict the yielding and flow dynamics of such complex materials in pure extensional flows. We find a significant deviation of the ratio of the elongational to the shear yield stress from the standard value predicted by ideal viscoplastic theory, which is attributed to the normal stresses that develop in the solid state prior to yielding.

Toothpaste, face creams, hair gel, mayonnaise and ketchup are household items that most people don’t think twice about, but in terms of their flow behavior, they have unusual properties. They’re all elasto-visco-plastic (EVP) materials, which behave like solids when at rest, but can yield to flow like liquids when placed under enough stress. Despite their ubiquity, the ability to model and predict their behavior relies on a theory that has only been shown to work under certain conditions.

Scientists from the Micro/Bio/Nanofluidics Unit at the Okinawa Institute of Science and Technology Graduate University (OIST) and the Laboratory of Fluid Mechanics and Rheology at the University of Patras have revealed insights about these materials by combining experiments with simulations. Their research, published in PNAS, suggests that the materials’ elasticity in its solid-like state is a key property that should be included in future models.

“Over the last decade, advances in microfluidics experiments have revealed many unexpected phenomena in the flow of EVP materials,” said Professor John Tsamopoulos, from the University of Patras. “Examples include the cusped shapes of bubbles in the gels and the loss of symmetry in the flow. These and other observations hinted that something was missing from the existing theory. Previous research in our lab suggested that elasticity, the ability of the material’s microstructure to deform before yielding, was the missing part of the puzzle.”

Professor Amy Shen, who leads the OIST Unit, said, “Even when basic household items are set aside, having a fundamental understanding of how EVP materials flow is very useful, especially in biomedical science and geophysics.” For example, she explained, blood is an EVP material—it behaves like a solid at rest, but flows like a liquid in arteries. What’s more, she added, some 3-D-printed tissues and scaffolds can have EVP properties, and, on the geophysics side, volcanic lava behaves like an EVP material albeit on a much larger scale.

Previous experimental research on EVP materials has measured their behavior under shear flow, obtained when layers of fluid slide past each other. But, when it comes to the industrial processing and uses of these materials, such as fiber-spinning and circuit-board printing, it’s often the extensional flow—when the fluid is stretched—that’s more important.

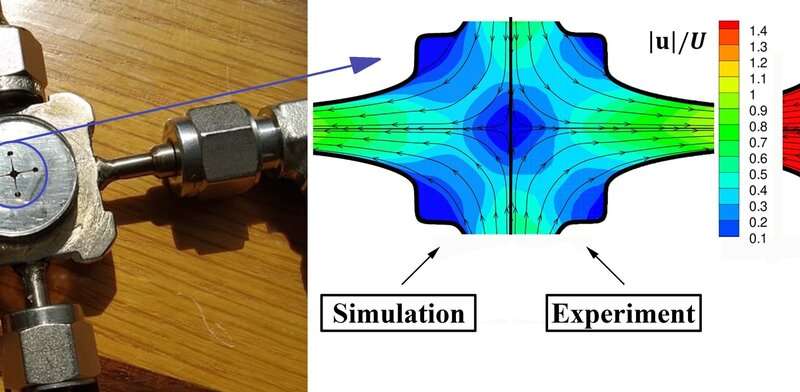

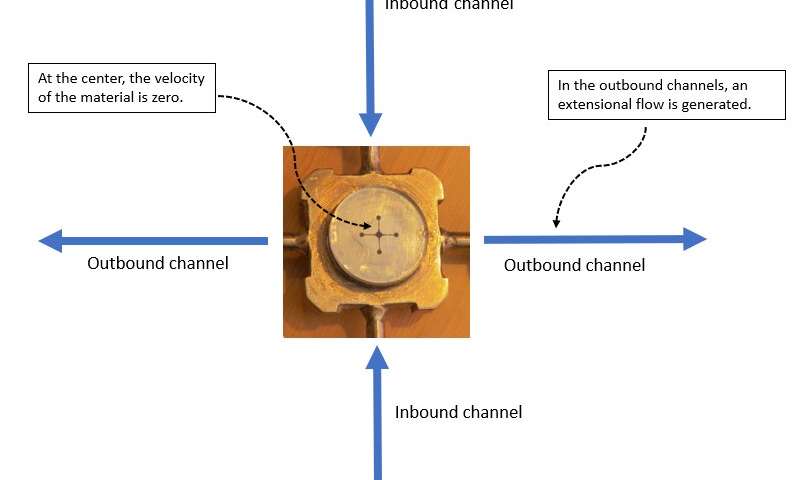

The study of purely extensional flows is a great challenge in experimental fluid dynamics, and the extensional flow of EVP materials has never previously been successfully measured in experiments. To achieve this for the first time, Dr. Simon Haward, the group leader from the Micro/Bio/Nanofluidics Unit, used a novel microfluidic apparatus known as a cross-slot geometry. The apparatus comprised four channels that were all at right angles to each other.

“Inside the cross-slot geometry, we used a Pluronic solution, a well-known EVP material,” said Dr. Haward. “When we put pressure on the two inbound channels, which were located opposite to each other, the solution was pushed towards the center point and it came out of the other two channels. The resulting flow has a point at the center where the velocity goes to zero. In the two outbound channels, we generated an extensional flow where the fluid was stretched.”

Meanwhile, Professor Yannis Dimakopoulos and researchers at the University of Patras created a theoretical model and simulated the flow of two EVP materials—the Pluronic solution and another material called Carbopol. They showed that complex patterns arose in the flow, which included the presence of solidified regions surrounded by the liquid-state. Their findings matched the experiments performed at OIST.

“This model can describe simple EVP materials in shear, extensional and mixed flows. Although we only focused on two materials, it could be used on a wide variety with varying levels of elasticity, plasticity, viscosity, and other properties,” said Stelios Varchanis, a Ph.D. candidate at the University of Patras and first author of the paper. “This makes the model appropriate for simulating flows during the design and optimization of various industrial processes.”

This research suggests that the existing theory needs to be overhauled to include the elasticity of the material. “Depending on the amount of deformation that the EVP material can sustain before yielding, it will either behave in a way close to what is predicted by the existing theory or will behave more like a flowing elastic-solid,” said Stelios.

“The experiments at OIST complimented the simulations,” said Dr. Cameron Hopkins, from the OIST Micro/Bio/Nanofluidics Unit. “Even though the Pluronic solution that we studied only exhibits weak elastic effects, a small amount of asymmetry was observed in the flow indicating a deviation from purely fluid-like behavior, so the elasticity cannot be neglected. Our experiments provided strong support for the proposed modification of the theory.”